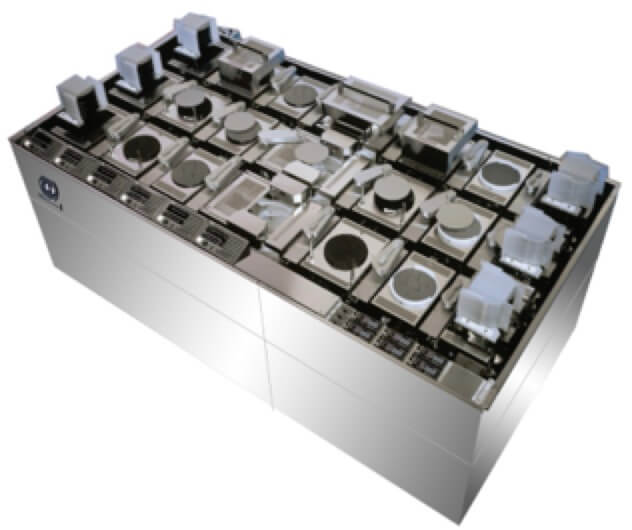

Main characteristic index∶

Materials∶

Polypropylene or stainless steel(304);

Options quartz groove;

Microcomputer temperature controller∶

In groove temperature variation <±1.0℃(@50℃);

Outside groove circulating heating system∶

Reliable and easy maintenance;

Overheating and water level alarm, water can be added automatically to maintain the water level;

(electroplating) hanging plating bath,4- point cathode contact;DC/pulse power supply;

Options PLC Touch-screen control;

.jpg)

.jpg)

Magatherm石英槽

.jpg)

过滤系统

.jpg)

循环加热系统

2.2 Precision Diamond Manual Scriber

America Dynatex International

.jpg)

Parameters |

GST-100 |

GST-150 |

| wafer size | Max 100mm | Max 150mm |

| wafer thickness | 40-1725μm(associated with the materials) | |

| scratch width | <5μm | |

| minimum step distance | standard 5μm (options 2μm) | |

| scribing speed | max 100mm/sec | |

| collapse piece speed | 2-4 breaks/sec | |

| collapse piece means | back side rapid air rush rod (British patent) | |

| graphic recognition vision system | auto-registration,pattern recognition,automatic delineation, automatic step and calibrate step error according to the set | |

| materials | GaAs,inP,GaP.Silicon,Saphire,Quartz | |

| user controllable parameters | cutting angle, drag force, scribing speed, entry speed of knife, collapse piece force, any few number core size | |

.jpg)

.jpg)

.jpg)

2.3 Wafer Expander

America Dynatex International

| product characteristics: | |

| size: | wafer size 6" or smaller, 5", 6" or 7" hoop group |

| rapid: | rapid periodic time fix the tape to hoop group and expand |

| precision: | suitable for picking and laying equipment |

| best expansion: | constant temperature control and fully adjustable heating platform optimization expansion |

| clean: | no physical contact between the chip and the controller |

| technical index: | |

| max Hoop group size: | 7" |

| maximum chip size: | 6" |

| temperature range: | 100-450C℃ or 40-230℃ |

.jpg)

.jpg)

2.4 Ball/Wedge Wire Bonding

Germany Technical Product Trade (TPT)

HB30

.jpg)

HB05

HB16

| Manual machine | Semi-automatic--1 | Semi-automatic--2 | Semi-automatic heavy duty aluminum wire | |

| wedge bonding | HB02 | HB06 | HB12 | HB30 |

| ball bonding | HB04 | HBO8 | HB14 | no |

| wedge bonding + ball bonding | HB05 | HB10 | HB16 | no |

| parameters | Manual machine | Semi-automatic--1 | Semi-automatic--2 | Semi-automatic heavy duty aluminum wire |

| wedge bonding | 17-75um | 100-500um | ||

| tape bonding | 25*250um | no | ||

| ball bonding and jump pier bonding | 17-50um | no | ||

| multipoint bonding | no | yes | ||

| direction control | XYZ manual | Z automatic | Z and Y automatic | |

| parameter setting interface | 4.1 inches LCD,hand wheel adjustment | 6.5 inches touch screen | ||

| automatic height | no | yes | ||

| radian control | no | highly controlled | highly and radian controlled | |

| bondarm length | 165mm | |||

| deep mobile | 19mm | |||

| programs stored | 20 | 100 | ||

| wire feed rolls | 2 inches hand-operated | 2 inches electrodynamic | 4 inches hand-operated | |

| fine mobile range | 10*10mm | 15*15mm | ||

| handle and head movement rate | 6:1 | 6:1 (options 3:1) | ||

| ultrasonic frequency | 62khz | |||

| ultrasonic frequency (max) | 5w | 50w | ||

| solder and sample contacting time | 20-1000ms | 15-2000ms | 0-10s | |

| welding force (unit: 1% cN) | 15-130 | 15-150 | 50-1800 | |

| built-in heating stage | 250℃(max) | no | ||

| illuminating system | double LED fiber-optics guided | double halogen lamp fiber-optics guided | ||

| chips Pick & Place | options | no | ||

| built-in tension tester | no | options | no | |

| copper wire welding | options | no | ||

| laser positioning | options | |||

| power requirements | 100-240V/10A | |||

| weight | 29kg | 42kg | 50kg | |

| remarks | HB05=(wedge)+HB04(ball) | HB10=HB06(wedge)+HB08(ball) | HB10=HB12(wedge)+HB14(ball) | |

AS-Micro

AS-One

AS-Master

| Characteristic | AS-Micro | AS-One 100 | AS-One 150 | AS-Master |

|---|---|---|---|---|

| max substrate dia | 75mm | 100mm | 150mm | 200mm |

| chamber size | 85dia×25mm | 130dia×25mm | 200dia×25mm | 300dia×25mm |

| temperature range | RT-1250℃ | RT-1500℃ | RT-1300℃ | RT-1500℃ |

| heating rate | 0.1-250℃ | 0.1-200℃ | 0.1-150℃ | 0.1-200℃ |

| temperature control | rapid digital PID | rapid digital PID | rapid digital PID | rapid digital PID |

| process gas line | 3 | 5 | 5 | 6 |

| AS-Micro main technology parameters |

|

AS-Micro/more~

| Technology parameters | AS-One 100 | AS-One 150 |

| sample size | 100 mm(") | 150 mm(") |

| vacuum chamber size | 130 mm diameter x 25 mm | 200 mm diameter x 25 mm |

| lamps numbers/max power | 12 / 30 kW | 18 / 34 kW |

| max heating temperature (high temperature options) | 1250C (1500C) | 1200C (1300C) |

| heating rate | 0.1C to 200C/s | 0.1C to 150C/s |

| cooling mode | air cooling | |

| thermocouple | 2 K type(one center and one edge) | |

| cryometer range | 150C to 1100C | |

| pyrometer range | 400C to 1500C | |

| infrared pyrometer | 2 (one center and one edge) | |

| process gas line | max 5 | |

| vacuum range | 10E-3 Torr (Roughing) 10E-6 Torr (Turbo) | |

AS-One/more~

| Parameters | S20 | S20 HT | 2000 | 2000HT |

| max temperature | 1150°C | 1500°C | 1250°C | 1500°C |

| heating zone | 6 | 6 | 10 | 10 |

| max power | 75 kW | 105 kW | 90 kW | 105 kW |

| max sample size | 200mm dia or 200mmx200mm rectangle | |||

| vacuum chamber | water-cooling, stainless steel chamber wall, low noise | |||

| heating | infrared partition heating, air cooled the lamp tube | |||

| temperature control | thermocouple and pyrometer control with PID | |||

| vacuum range | 10E-3 Torr (Roughing), 10E-6 Torr (Turbo) | |||

| process gas line | max 6 | |||

| control method | computer control, provide more than 100 processing procedures with different requirements | |||

AS-Master/more~

| Applications | RTA, RTO, Reflow, Implantation annealing… |

| Substrate size | up to 6-inch diameter samples |

| Temperature max | 1300°C (depending on furnace version) |

| Temperature ramp rate | 150°C/s on 4-inch silicon wafer (depending on version) |

| Temperature control | multi-zone, thermocouple or pyrometer, fast PID |

| Vacuum capability | 10-3 Torr (10-6 Torr option) |

| Gas lines | up to 6 gas lines with MFC and one purge line with needle valve |

| Loading | manual, optional cassette to cassette or load-lock |

| Applications | Silicon Carbide implantation annealing, Graphene on SiC… |

| Substrate size | up to 4-inch diameter samples |

| Temperature max | 2000°C up to one hour |

| Temperature ramp rate | 4°C/s up to 1800°C and 2°C/s up to 2000°C |

| Temperature control | thermocouple and pyrometer, fast PID |

| Vacuum capability | 10-6 Torr |

| Gas lines | up to 8 gas lines with MFC and one purge line with needle valve |

| Loading | manual |

2.6 CMP System

Revasum

| Table Motor Size/Cntrl | 5 Hp w/ AC Var.SpeedDrv |

| Table Diameter | 22” [~560mm] |

| Oscillation Stroke | Adjustable |

| Slurry System(s) | 2 Std/ 3rd optional |

| Slurry In/Out | ~3 GPH |

| Dimensions (SAE) | 48”W x 51”D x 72”H |

| Dimensions (Metric) | 1.2M x 1.3M x 1.8M |

| Footprint | ~17 Ft² [~1.57 M²] |

| Weight | ~1800 lbs [~820 K] |

| Wafer Capacity | 100mm to 200mm |

| Control System | PC-DOS 2000 |

| Wafer Handling | Manual Wafer Load |

| Configuration | 1 tables, 1 polish head |

2.7 P8010 Advanced Linear Track System

America C&D Semiconductor Services Inc.

| P8010 Technical Data | |

| Available modules | Coater, developer, hot plates, chill plates, vapor prime |

| Transfer Method | Automatic transfer arm with improved design maintaining end-point placement to within ± 0.1 mm over 300,000 wafers |

| User Interface | Windows-based operating system with smartPro GUI |

| Transfer Mode | Serial transport |

| Indexer | SEMI standard H confguration |

| Coater | Spin motor: 50 RPM-9500 RPM in 10 RPM increments (Optional brushless motor with digital controller) # of Dispenses: Up to four Solvent nozzles: Top and bottom EBR |

| Developer | Spin motor: 50 RPM – 9500 RPM in 10 RPM increments (Optional brushless motor with digital controller) Stream and spray nozzles |

| Hot Plate | Hot plate temperature: Up to 300˚C (optional temperature to 400˚C) Uniformity: ±0.5% (50˚C -300˚C) Bake method: Contact or fxed/programmable proximity options |

| Chill plate | Standard house chilled water Optional high efciency chiller at ambient ± .1˚C – Option |

| Vapor Prime | Temperature range25˚C to 190˚C Method: Programmable and/or fxed proximity bake capability |

2.8 P8060 Copper Bump Developer

America C&D Semiconductor Services Inc.

| P8060 Technical Data | |

| Available modules | Copper bump developer |

| Wafer size | 50 mm - 200 mm wafers |

| Transfer Method | Automatic transfer arm with improved design maintaining end-point placement to within ± 0.1 mm over 300,000 wafers |

| Transfer Mode | Serial transport |

| User Interface | Windows-based operating system with smartPro GUI |

.jpg)

.jpg)

2.9 P8000 Track System

America C&D Semiconductor Services Inc.

| P8000 Technical Data | |

| Available modules | Coater, developer, hot plates, chill plates, vapor prime |

| Wafer Size | 88X 50 mm - 200 mm 86X 50 mm - 150 mm |

| Transfer Method | 88X - Automatic transfer arm 86X - Belt transfer |

| User Interface | Card cage control (with optional Recipe Master for 88X) |

| Transfer Mode | Serial transport |

| Indexer | SEMI standard H confguration |

| Coater | Spin motor: 50 RPM – 9500 RPM in 10 RPM increments (Optional brushless motor with digital controller) # of Dispenses: Up to four Solvent nozzles: Top and bottom EBR |

| Developer | Spin motor: 50 RPM – 9500 RPM in 10 RPM increments (Optional brushless motor with digital controller) Stream and spray nozzles |

| Hot Plate | Hot plate temperature: Up to 300˚C (Optional temperature to 400˚C) Uniformity: ±0.5% (50˚C -300˚C) Bake method: Contact or fxed/programmable proximity |

| Chill plate | Standard house chilled water Optional high efciency chiller at ambient ± .1˚C – Option |

| Vapor Prime | Temperature range25˚C to 190˚C Method: Programmable and/or fxed proximity bake capability |

2.10 P9000 Cluster System

America C&D Semiconductor Services Inc.

| P9000 Technical Data | |

| Feature Sizes | ≥ .35μ Resist dependent and assumes temperature/humidity control within fab of ±1.0ºC and ± 3% relative humidity. |

| User Interface | Windows-based operating system with smartPro GUI |

| MTBF | ≥ 500 hrs, or 12,000 wafers (Based on C&D’s PM schedule) |

| MTTR | ≤ 1 hour |

| Uptime | 95% or better |

| Wafers Broken | 1 in 10,000 wafers |

| Reliability | 95% uptime in volume process manufacturing |

| System throughput | 100+ wafers per hour (Configuration & Process Dependent) |

.jpg)

.jpg)

2.11 P7000 Efficient Alloying Furnace

America C&D Semiconductor Services Inc.

| Model | SmartPro P7000 |

| wafer size | 2-8inches |

| temperature | up to 500°C |

| speed | 20piece/h |

| major advantage | reliable, simple and efficient, realized the chip box (C to C) function |

| infinitely close heating mode,heating plate non-touch the back of wafer, low warping, high uniformity and high repeatability | |

| multiple gas, controlled environment and slow cooling | |

| by varying the distance between the wafer and the heating plate to control the heating rate | |

| manual and automatic control, efficient, twice as efficient as RTA | |

| higher cost performance |

.jpg)

| Model | MC050 | MC100 | MC200 |

| wafer size | 2 inches | 4 inches | 8 inches |

| applications |

semiconductor: SiO2, HfO2, Ta2O5, Cu, TiN, TaN, ... |

||

| temperature | up to 1200°C | up to 850°C | up to 850°C |

| vacuum | barometric pressure——10E-3 Torr | ||

| evaporator | up to 6 | up to 4 | up to 4 |

| gas circuit | Up to 6,MFC control | ||

| process chamber | quartz tube (water-cooled stainless steel flange) | controllable temperature stainless steel wall, rotating sample seat | controllable temperature stainless steel wall, rotating sample seat |

| heat | halogen lamp | resistance wire | resistance wire |

| temperature control | fully digitized PID control | ||

| Model | SprayCVD 050 (also used for annealing) |

| wafer size | 2*2 inches |

| applications |

implantation annealing |

| temperature | room temperature——1200°C |

| vacuum | barometric pressure——10E-3 Torr |

| gas circuit | up to 3, MFC control |

| process chamber | quartz tube (water-cooled stainless steel flange) |

| heat | halogen lamp (upper and lower heating modes are available) |

| temperature control | fully digitized PID control |

| Model | Benchark 800 |

| characteristic | 1—8 inches |

| up to 6 process gases, MFC control | |

| equipped with a water-cooled electrode for ion etching | |

| hot bottom electrode plate and water-cooled electrode plate,used to enhance PECVD | |

| etch (SiO2&Si3N4):100°C/1500 2000Amin/ Uniformity +/-5% | |

| enhanced plasma CVD(PECVD)(SiO2&Si3N4):300°C/500Amin/ uniformity +/-5% |

| Model | PlasmaStar |

| characteristic | 12 inches * 14 inches plasma region |

| up to 4 process gases, MFC control | |

| parallel electrodes, upper electrode with a spray head,lower electrode with the function of water cooling | |

| optional cage electrode |

| Model | PlasmaStar |

| characteristic | 12 inches * 14 inches Plasma region |

| up to 4 process gases, MFC control | |

| parallel electrodes, upper electrode with a spray head,lower electrode with the function of water cooling | |

| optional cage electrode |